CISRI Engineering Design Co., Ltd. is subordinate to China Iron & Steel Research Institute Group (CISRI), a central enterprise directly managed by the SASAC of the State Council. It is a key member of CISRI and a leading enterprise in the EPC industry chain in the metallurgical equipment field of CISRI. It is a scientific and technological enterprise focusing on engineering technology research and development, design consulting, EPC engineering contracting, electromechanical contracting, and related new product development. Its headquarters are located in Haidian District, Beijing.

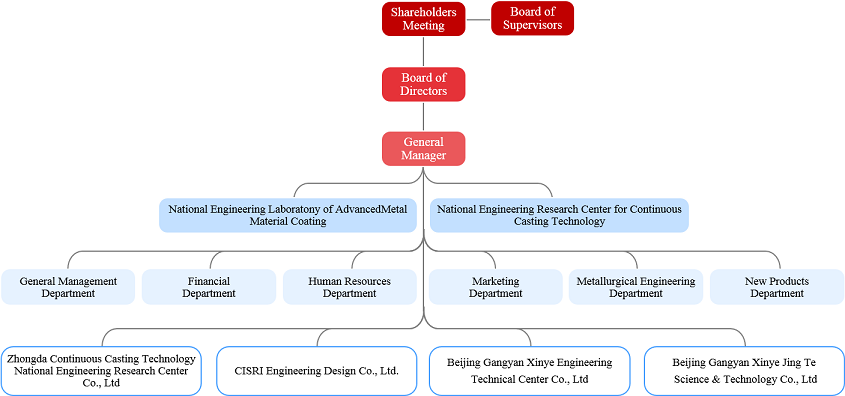

In 2019, CISRI implemented a strategic restructuring of the group's engineering sector, establishing an engineering division, and at the end of 2020 CISRI Engineering Design Co., Ltd. was founded. CISRI Engineering Design Co., Ltd. integrates engineering resources under CISRI, complementing each other's advantages, and constructs a full industry chain support system from planning, consulting, design, and construction, as well as a production and maintenance lifecycle operation service system. It has multiple national research and development platforms such as the National Engineering Laboratory for Advanced Metal Material Coating, the National Engineering Research Center for Continuous Casting Technology, and the Beijing Key Laboratory for Special Ceramics and Refractory Materials, as well as metallurgical design, construction and other qualifications.

The company is the only engineering company in China that has achieved the integration of production and research in the field of cold rolling and coating. It is the most professional design, research and development institution in the field of high-quality thin plate. It has formed a total contracting capacity for the entire process of cold rolling post processing with coating engineering as the core and scientific research achievement transformation as the traction, and has become a leading enterprise in the field of deep processing of plate and strip coating in China. Currently, nearly 300 large-scale continuous strip processing production lines have been successfully designed and promoted, including pickling production lines (PPL), acid regeneration plant (ARP), continuous hot dip galvanizing (aluminum) and galvalume production lines (CGL), thermal/radiation curing color coating production lines (CCL), continuous annealing production lines, continuous decarburization annealing coating production lines of silicon steel, electrolytic cleaning production lines (ECL), strip finishing production lines, continuous electrotinning production line, and etc. After years of experience accumulation, the company has formed a complete set of quality management systems and technical service systems in product quality control, unit performance optimization, equipment and product upgrades, and technical services, providing a strong guarantee for better service to customers.

The company has achieved multiple EPC and product supply achievements in the fields of process furnaces, ceramics, ironmaking, environmental protection and solid waste treatment. The company has been designing and manufacturing industrial furnaces since the 1970s, with a manufacturing history of nearly 40 years. It has formed a series of heating furnaces of various specifications such as special electric furnaces, pusher type heating furnaces, walking beam heating furnaces, roller hearth annealing furnaces, and baking furnaces; The company has production and processing equipment for silicon carbide ceramics such as mixing equipment, granulation equipment, cold isostatic pressing machines, carving and milling machines, processing centers, surface grinders, vacuum sintering furnaces, etc., which can achieve integrated production from silicon carbide powder granulation, molding, ceramic sintering, and processing. The products are widely used in integrated circuit manufacturing equipment, LED, photovoltaic, petrochemical, and other industries.

The company focuses on the production of ferroalloys and amorphous parent alloys and the development of new processes and products, gradually forming a business model with engineering projects as the core and engineering construction, scientific research and development as the main body. Currently, the main business areas include: ferroalloy products and engineering technology, engineering technology for non-blast furnace production of reduced iron powder, industrial environmental protection and solid waste treatment engineering technology, new smelting process development and engineering technology.

The ironmaking business includes tracking and research on cutting-edge ironmaking technologies at home and abroad, monitoring technologies and devices for ironmaking processes, experimental research and devices for ironmaking raw materials, and coal injection technology and devices. The main technologies and products include high-efficiency coal injection technology for blast furnaces, coke oven gas injection technology for blast furnaces, high-temperature furnace thermal monitoring technology, experimental research on sintering pellets, long-life spray guns, coal injection spare parts, continuous temperature measurement device for blast furnace molten iron, tuyere camera device Infrared imaging monitoring device for hot blast furnace, and etc.

In the field of continuous casting technology, the company owns key technologies with independent intellectual property rights, such as continuous taper mold copper tubes, mold hydraulic servo vibration, mold breakout prediction, large chamfer mold, secondary chamfering equipment, rapid cooling box, secondary cooling dynamic soft reduction, funnel mold, electromagnetic stirring, mold automatic width adjustment, etc. We have completed the construction and renovation of nearly 100 square billet and slab casting machines in China, and have rich experience and excellent performance in the field of continuous casting.

CISRI Engineering Design Co., Ltd. adheres to the corporate spirit of "customer first, honesty and trustworthiness, openness and sharing, and the pursuit of excellence"; In order to create a beautiful vision of "taking value creation as the guide, building an innovative, green, and intelligent metallurgical process ecosystem, and providing customers with comprehensive solutions for the entire industrial chain of metallurgical process engineering", we are striding forward!