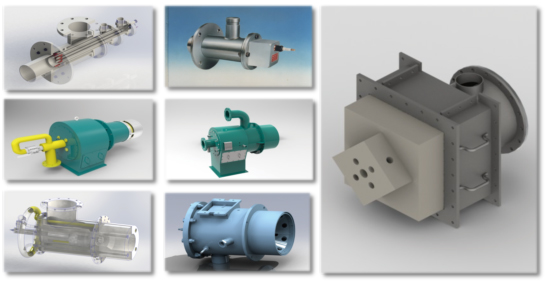

Low-nitrogen burner is an environmentally friendly burner developed by our company for the furnace users of iron and steel plants. Through a specially designed structure, relying on the entrainment effect of (high temperature) combustion air and fuel gas high-speed jet, the air flow in the burner chamber is effectively organized, so that a large number of combustion products can flow back in the combustor area, dilute the oxygen concentration in the combustion area, and achieve low nitrogen combustion.

Main Features:

There is no obvious flame boundary, the combustion volume in the cavity is large, and the reaction time and reaction space are significantly increased;

There is no local high temperature and high oxygen zone in the flame for traditional combustion, and the temperature field distribution is uniform;

Reduce the peak temperature of the flame and the volume concentration of oxygen in the combustion zone, greatly reducing the generation of NOX;

Reduce the volume concentration of oxygen in the combustion area and the unit intensity of combustion, resulting in lower combustion noise.

Burner Parameters::

Ø Suitable fuels: natural gas, mixed gas, blast furnace gas, liquefied petroleum gas, etc.

Ø Heating value range for fuel adaptation: 1200~11000 kcal

Ø Power ranger: 0.4 to 7 MW, non-standard customizable