Main Technical Performance Index:

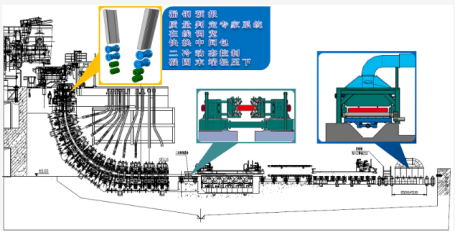

In view of various surface defects in the continuous casting process of micro-alloyed steel, the key technologies for controlling edge seam defects and warping defects of plate and strip, the control process and equipment technology for hot charging and hot delivery cracks, and the control technology for transverse corner cracks of micro-alloyed steel are mainly broken through, and a systematic and complete process and equipment are developed to realize the integration and application of key technologies. Increase the yield of steel by 1%, and realize the cold charging of micro-alloyed steel from offline cleaning to stacking at 550 ℃, and then to rapid cooling and direct charging at an average temperature of 750 ~800 ℃. It is assisted by intelligent control software and processes such as breakout prediction, quality judgment expert system, online width adjustment, quick-change tundish, secondary cooling dynamic control, solidification end soft reduction, etc., to realize the engineering application of green and efficient manufacturing technology for typical steel processes, and to reduce costs, save energy and increase efficiency for steel enterprises.