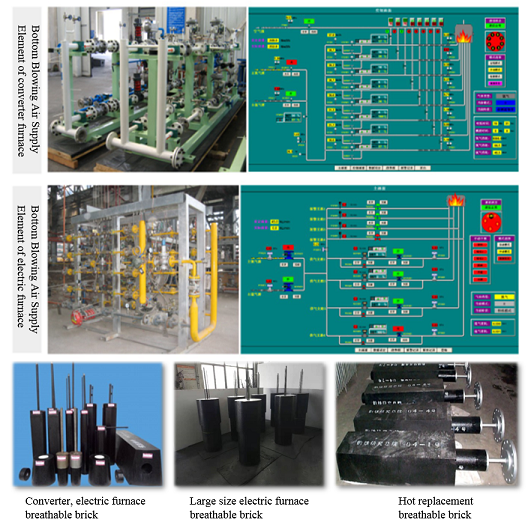

The bottom blowing gas supply element (permeable brick) for steelmaking is a key functional part of the bottom blowing mixing system of the converter and electric furnace. It is built on the furnace bottom. During steelmaking, gas is blown in to increase the stirring power of the molten steel. The bottom blowing gas source is N2, Ar, CO2 and other gases. The gas supply intensity can be adjusted in the range of 0.01~0.2Nm3/min·t and can be customized according to customer requirements. Our company can also provide the design, manufacturing, and commissioning of the bottom blowing gas supply system.