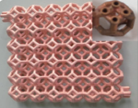

Copper aluminum composite liquid cooling plate is a heat dissipation component that uses copper as the liquid cooling channel and is composed of aluminum alloy. It can fully utilize the high thermal conductivity of copper and the high heat dissipation and lightweight characteristics of aluminum, solving the efficient heat dissipation needs of modern high-power electronic devices. Our company has broken free from the limitations of traditional processing and welding of liquid cooling plates, and comprehensively utilized self-developed low-cost pure copper 3D printing technology, surface graphene modification technology, differential pressure casting technology, etc. to develop a new controllable structure copper aluminum composite liquid cooled plate preparation technology.

Our company can currently prepare ultra-thin cooling plates with a maximum size of 0.5 * 0.5m, with a thickness controlled within 5mm and a minimum diameter controlled to 1mm. The shape, specifications, and dimensions of the cooling plate can be customized according to user needs.